50 Years ago today (31/05/19) CPE moved to Tamworth.

In 1970, CPE moved to their current premises in Tamworth. During the 1970s CPE mainly produced filters and driers for compressed air systems. Innovative designs included cyclonic separators (a technique since used by vacuum cleaner manufacturers) multi stage filters and supremely reliable automatic drain valves. CPE also produced air receivers for their range of compressors and filter housings for their many designs of filters.

A lot has changed and a lot of progress has been made in the last 50 years, but we have managed to retain the family feel and values that we had 50 years ago.

When we first moved in we had the single workshop and small offices, below are some photos showing our progression and growth:

For more information on our history see the following link: Company History

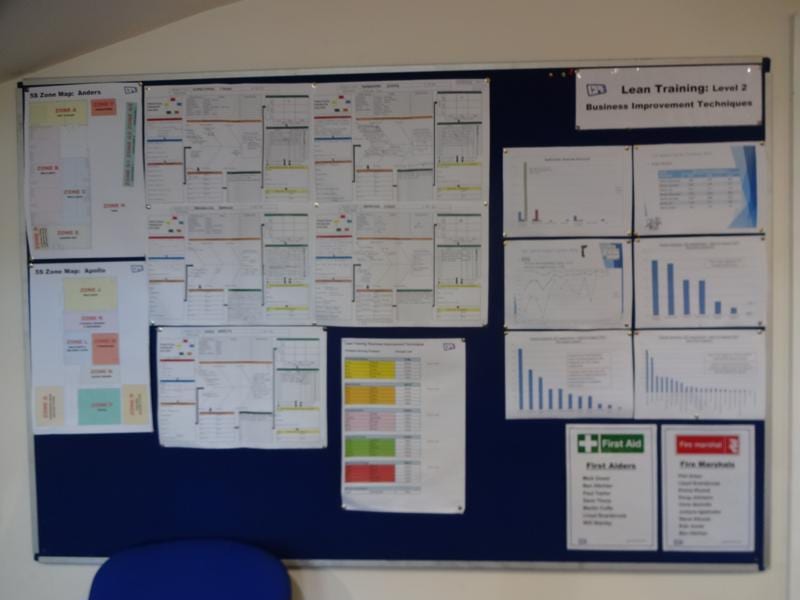

As part of an ambitious business change programme, CPE Pressure Vessels appointed In-Comm Training and Business Services to deliver a Level 2 Certificate in Business Improvement Techniques. The entire company workforce comprising both office and workshop teams completed the qualification over 18 months, with a 100% pass rate. Focusing on problem-solving techniques using real-world examples, the course has helped foster a culture of Lean Manufacturing and Continuous Improvement across all areas of the business.

A wide range of subjects and business improvement techniques were covered over the 18 month course, to name a few of the modules: Complying with statutory regulations and organisational safety requirements, Contributing to effective team working, Contributing to the application of workplace organisation techniques, Contributing to the application of continuous improvement techniques (Kaizen), Contributing to the development of visual management systems and Contributing to the application of problem solving techniques.

We covered a wide range of topics and all learning was focused towards CPE and using real and live projects to apply the various techniques as we studied them. We found that we made some great progress in developing various areas of the business during the course and we have continued to grow and progress with this.

We are now running an internal version of the course that will ensure any new employees are at the same level and that we have consistent methods throughout the company.

Fun health and safety workplace induction video made by CPE Pressure Vessels in 2018. Staring the employee’s children and relatives, the video covers general health and safety information for visitors to our site in Tamworth, UK.

CPE were registered 12/06/1948 and have been operating for 70 years.

We look forward what the the future will bring.

For more information on our company history please click here.

CPE were recently featured in the latest Fit 4 Nuclear news letter.

CPE were recently featured in the latest F4N news letter. Please see the article Linked below. The article is around an interview with Steve Newall covering the recent progression and development at CPE as part of the Fit 4 Nuclear Programme.

Click here to see new letter: Nuclear-AMRC-News-CPE-Pressure-Vessels-UK-Feature

CPE have recently won a project for the Johan Castberg Oil Field.

CPE have recently won a project for the Johan Castberg Oil Field. It’s great to see this project moving and we look forward to seeing similar projects in the future.

The field will be developed with an FPSO+ production vessel with additional sub-sea solutions, situated approximately 100 kilometres north of the Snøhvit-field in the Barents Sea first oil is expected in 2022 with an estimated 400 to 650 million barrels of oil.

For similar enquiries please contact us at: Sales@CPE-LTD.com

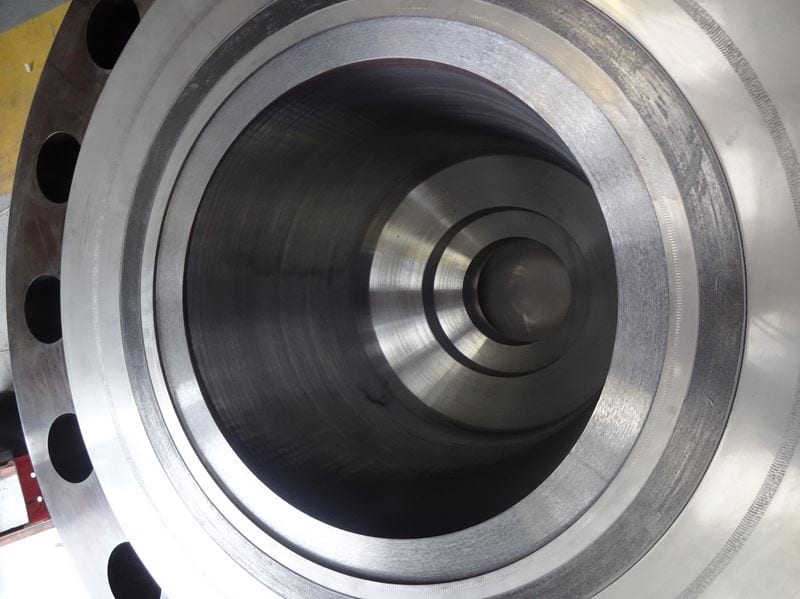

NGNP Project – A508 Material

CPE have manufactured pressure vessels using A508-4N material. The vessels were part of a project which was certified to both PD5500 Category 1 and ASME VIII Division 1. The vessels are destined to be used in both Europe and America. The scope of work included material control, design, welding, post weld heat treatment, post weld machining and testing of vessels from 50mm to 100mm wall thickness.

A508-4N is the preferred material for pressure vessels for the New Generation Nuclear Plant (NGNP) programme. It is a low alloy steel for operating temperatures up to 371°C.

The characteristics of the application and material require very tightly controlled quality heat treatments, weld procedures to ASME IX and ISO15614 and carefully controlled post weld heat treatment processes.

All work was carried out at CPE’s Tamworth workshops to the satisfaction of an unnamed UK nuclear company.

CPE have added a completely new workshop to their existing facilities, to be used for production of stainless steel vessels. The new workshop is situated just across the road from their existing premises, and represents a significant expansion to the current facilities.

The new shop has been purpose built for the manufacture of stainless steel pressure vessels, with high doors, heavy lifting and good working height. The new building contains seven welding bays, a purpose built pressure test area, a bead blast room and meeting facilities. 5s systems are being used throughout the building, increasing productivity.