We have made some improvements to our Anders workshop facilities, improving the safety, working conditions and look of the workshop.

We have upgraded the lighting to new LED lights giving 304500 lm and around a 50% reduction in power consumption. we’ve also added a resin floor and new welding curtains.

- LED lights giving 304500 lm

- 50% reduction in power consumption

- Fully segregated stainless steel workshop

We’ve now been in our purpose-built Anders workshop for 10 years. Anders is our fully segregated Stainless steel workshop where we produce the majority of our work, we regularly make Pressure Vessels, Air Receivers, Heater Housings, Filtration Vessels, DWI Water Vessels and Pipework.

Click here to see our recent Projects

Click here for more information on Pressure Vessels

Keep up to date with our latest news on LinkedIn

At CPE we take health and safety very seriously. We are pressure testing vessels and components up to 1200 Bar G every day. We use a combination of external & internal training courses to ensure our test bay operatives are always safe & aware of the dangers. Recently we’ve had some of the new team members attend a 2-day Hydrostatic Pressure Testing Training Course. They covered the practical and theoretical aspects of pressure testing, covering thread awareness and the tightening of connectors. We have invested heavily in purpose-built pressure rigs, pumps & bulletproof screens to keep risk to a minimum.

For more information on our HSEQ Assurance click here

Click here for more information on Pressure Vessels

Keep up to date with our latest news on LinkedIn

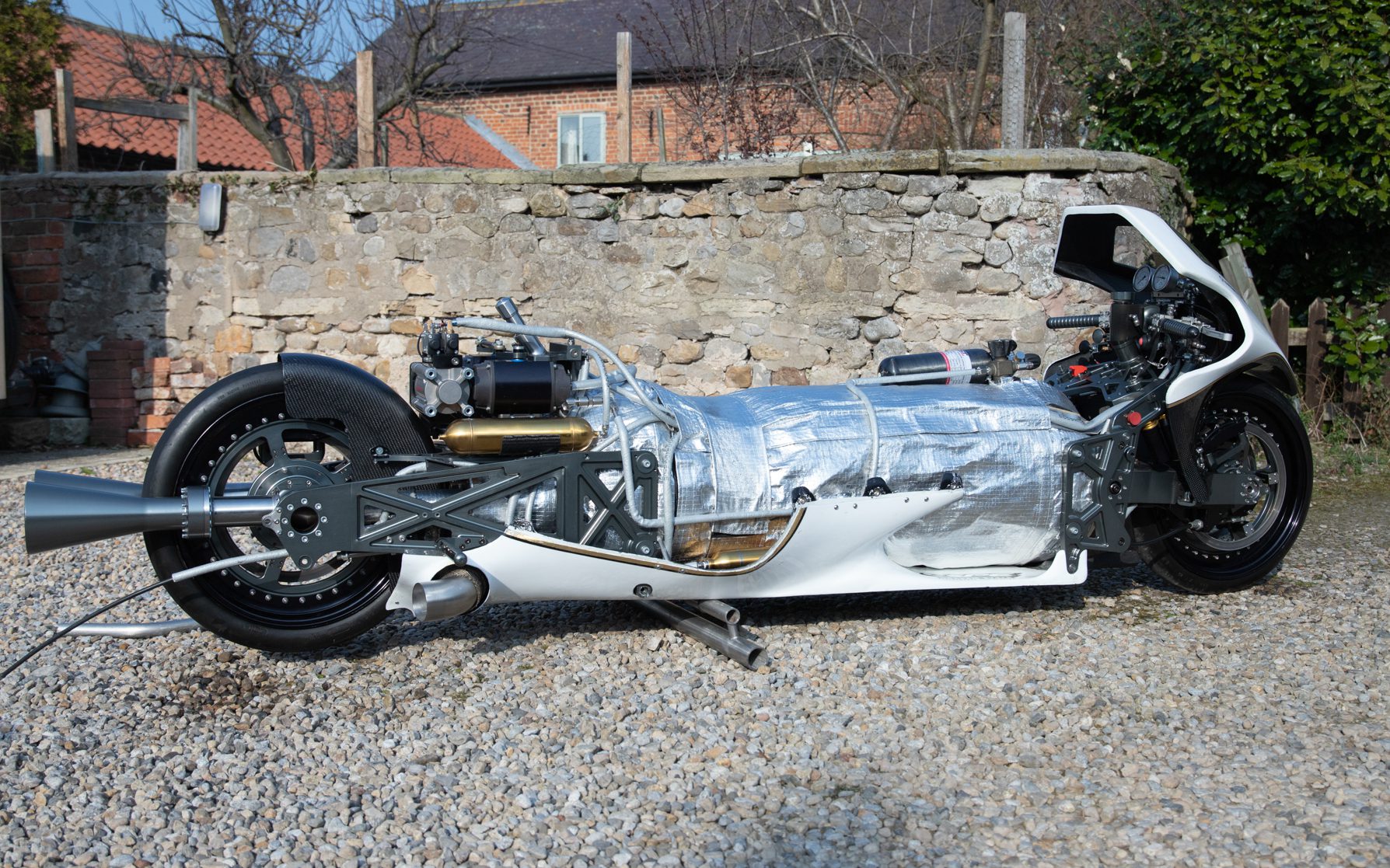

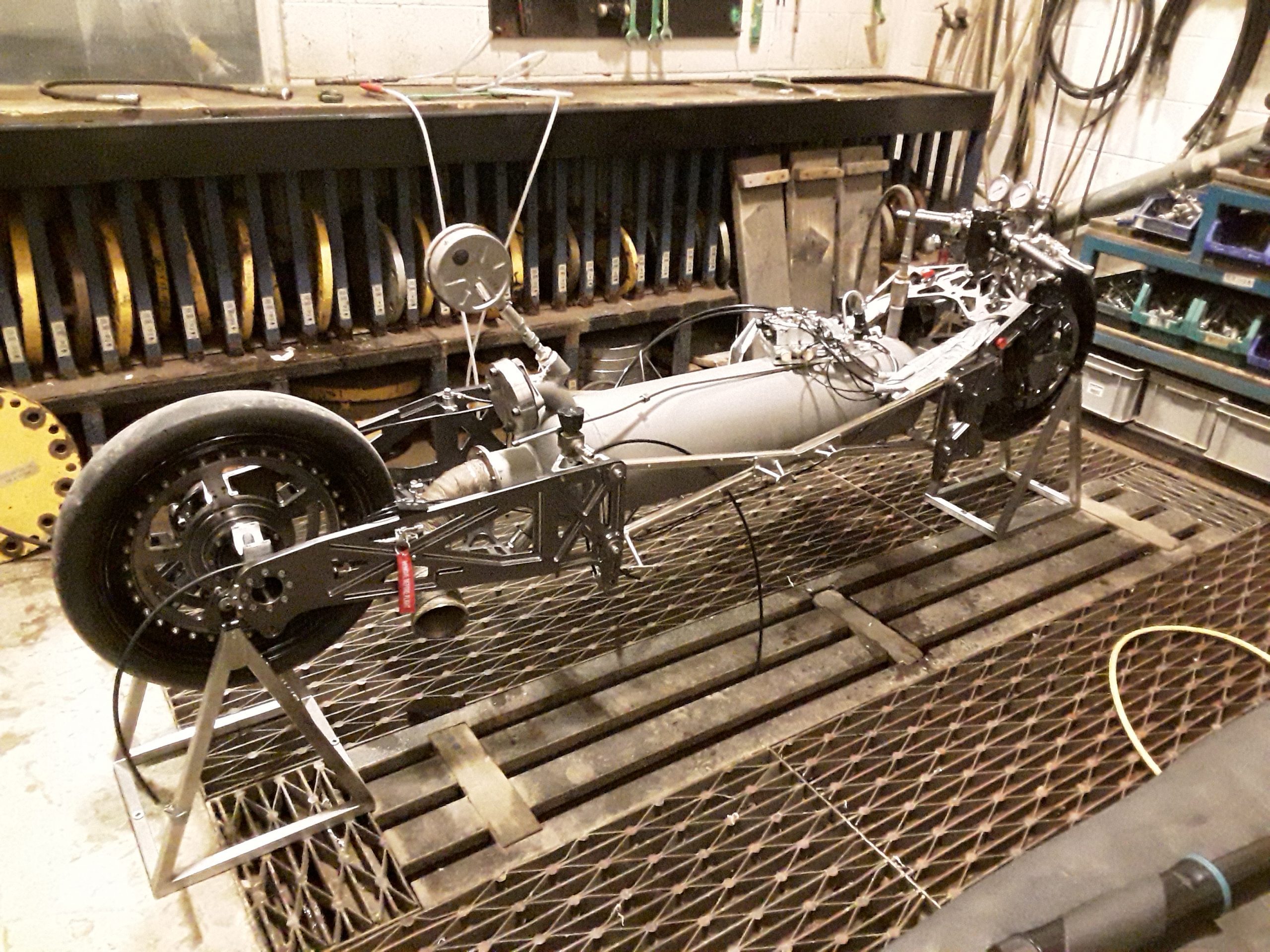

Over the last 10 years, we have supported Graham Sykes on his Force Of Nature Steam Rocket Bike project. The project aimed to produce a steam-powered rocket bike with unique green credentials and the potential to reach 200mph making it the fastest Steam powered vehicle ever.

The bike works by superheating pure water to create pressure. Once the correct pressure is achieved the water is then passed through a specially shaped nozzle, the superheated water flashes to steam as it escapes through the de Laval nozzle creating rocket propulsion until the bike’s pressure vessel is empty. The heat is generated by using hydrogenated vegetable oil to reach 200°C and 30 bar pressure.

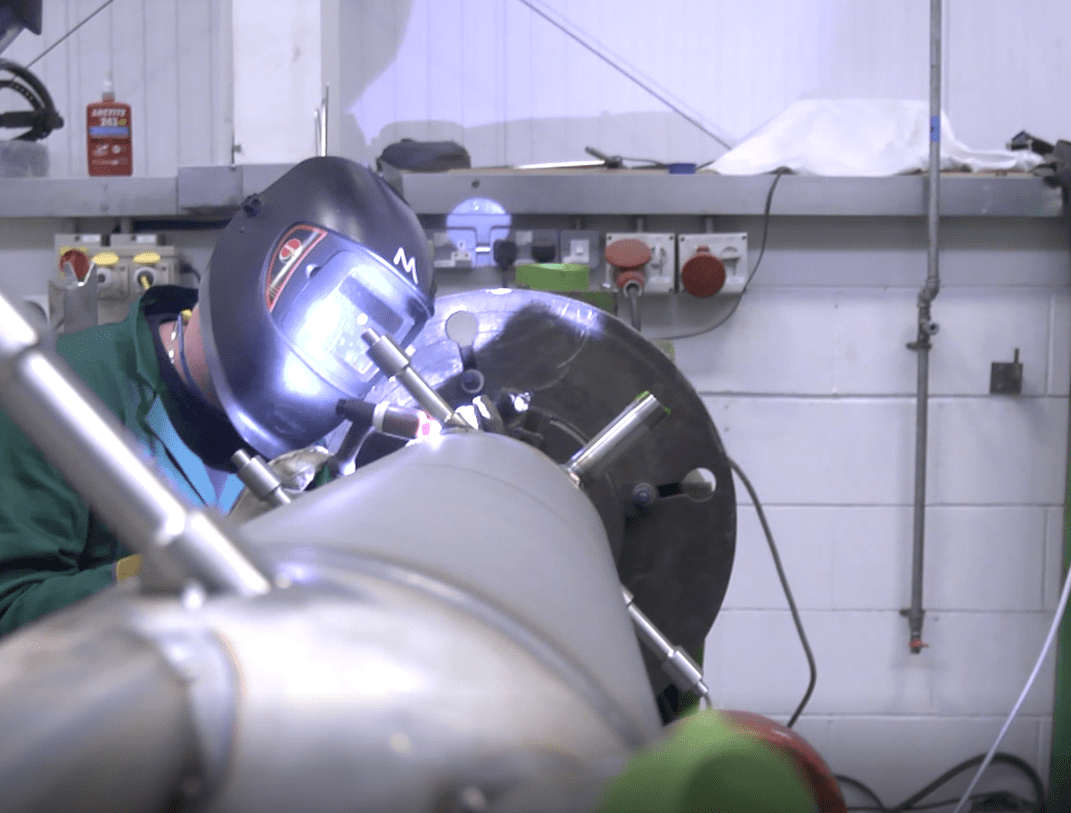

We designed, manufactured and certified the pressure vessel to meet Graham’s specifications at our Tamworth facility. The vessel required custom-made parts and specific dimensions to help optimise the bike’s performance. Initially, we made a 50 litre Stainless Steel 316/L vessel and then after testing we made a 130 Litre vessel to increase the capacity of the bike, heating tubes run through the vessel to get the water to 200°C.

Team Force of Nature:

The force of nature team is a small family-run precision engineering company, Graham Sykes and his wife, Diane.

Chief designer and engineer Graham Sykes has been involved in straight-line motorsport since 1979. Graham has worked on many prestigious projects including six years as race engineer for Vauxhall’s championship-winning British and European Touring Car Team, engineer and key team member for the ‘Firestorm’ jet-powered dragster and is currently part of the engineering team working on ’52 Express’, a world land speed record motorcycle. Graham is the current British land speed record holder for a 3-wheeled vehicle achieved with his self-designed and engineered V8 engined ‘Syko’.

Graham’s wife Diane takes on the role of financial director and purchaser. Not unfamiliar with motorsport Diane has been inherently involved in running the bikes for the last 22 years; crewing for the team on the start line and towing the bike back after completing runs. Diane’s strengths also come into play with the administration/accounts, travel logistics and hospitality, something every project is lost without.”

A full article was featured in Race Engine Technology – Issue 139

For more information on the Force Of Nature project: Force Of Nature Website and Facebook Page

for more on CPE see the following links:

Click here to see more Projects

Click here for more information on Pressure Vessels

Keep up to date with our latest news on LinkedIn

Thanks to Graham Sykes and Becki Ellis Photography for the photos.

Congratulations to Mitul for getting his CSWIP Visual Welding Inspection qualification. Mital is a vital part of our quality team whose role is to help to maintain our high standards across all our products. The CSWIP Visual Welding Inspection course is aimed at welding inspectors and will help to improve their inspection skills. At CPE we are constantly investing in our team and looking to improve our skills.

For more information on our design and technical capabilities click here

Click here to see more Projects

Keep up to date with our latest news on LinkedIn

CPE are delighted to announce that we are opening a new facility the Neander Works which will be a Clean Energy Workshop. Located in close proximity to our existing two workshops and head office. Neander Works will service our increasing demand for fabrications in the Clean Energy Sector. The requirement to increase our capacity came following securing major contracts for the Hydrogen Market.

For more information on how we support the Clean Energy Industry see the Clean Energy Page or get in contact

Keep up to date with our latest news on LinkedIn

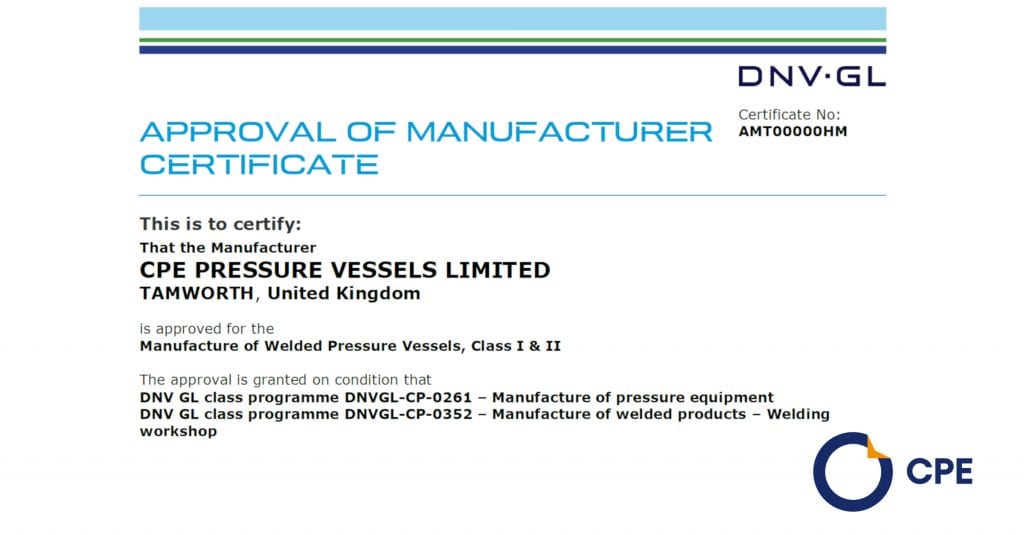

DNV Approved Manufacturer, at CPE we are proud to have DNV approval for the manufacture and of welded Pressure Vessels Class I and II. This covers us for the manufacture of Pressure Equipment and the manufacture of welded products in our welding workshop.

“DNV approval of manufacturers (AoM) confirms that you have been found in compliance with international standards, regulations or our recognised DNV rules. This provides your company with proof of high quality and safety standards.”

See below for our DNV Certificate and for more information about what we can offer as a DNV Approved Manufacturer:

DNV Approval of Manufacturer Certificate

Click here for more information about Pressure Vessels

Keep up to date with our latest news on LinkedIn

Did you know CPE have ASME Accreditation?

At CPE we are proud to hold ASME accreditation, which enables us to design and manufacture Pressure Vessels in accordance with the ASME VIII Division 1 Boiler and Pressure Vessel Code. We can stamp pressure vessels with the ASME Certification mark with the U designator as well as the UM designator (miniature vessels) which is sometimes referred to as U and UM Stamp. The ASME VIII Div.1 accreditation covers the design, fabrication, assembly, and inspection of pressure vessels. We also possess the NBIC “R” stamp which enables us to perform repairs and alterations to pressure vessels already bearing the ASME certification mark with the U or UM designator.

The ASME BPVC is recognised globally and is used to meet local governments safety rules and regulations. The U Stamp is a clear sign that the vessels comply with the ASME guidelines and ensures that the product and supplier are committed to public safety and product quality. At CPE we have held ASME accreditation since 2008 and have supplied ASME U stamped vessels and products for projects in the UK, Europe, USA, Canada, Australia, Russia, the Middle East and many other locations.

Click here to see our ASME U and UM certification

For more information or any enquiries please get in touch. Contact us

Keep up to date with our latest news on LinkedIn

We have recently received type approval for CU TR 032 Category 3 & 4 Vessels, this enables us to EAC mark Pressure Vessels for Russia, Kazakhstan and Belarus. The certificate goes alongside our category 1 and 2 type approvals meaning we are now able to manufacture and certify a wide range of vessels to CU TR 032 in-house, for more information or any enquiries please get in touch.

CU TR 032 Cat 3 and 4 Certificate

CU TR 032 Cat 1 and 2 Certificate

The company background and history from the 19th century till present – over 100 years in business.

From Victorian times to WW2

At the turn of the 19th Century, John Newall (Jack Snr) founded an import export business, based in the centre of Manchester. The company, John Newall & Co imported products such as Cyprus lace and wine, Egyptian cotton, Russian oils and rugs. Many of the imported items were sold to retail outlets.

Jack Snr and wife Mary (aka Mimi) also ran a haberdashery shop in Broom Lane, Levenshulme, Manchester, where they sold many of the imported goods. In return, they exported high technology items such as machinery, pumping equipment, pipework, tractors, diesel engines and threshing machines.

In 1900, Jack Jnr was born and was soon to become a central figure of the business.

At the age of 22, Jack Jnr spent much time in Cyprus and the Middle East, trading many goods and revolutionizing the lives of many. John exported many high tech products, including pioneering agricultural equipment to some countries. He is thought to have exported the first tractor from England to Cyprus, and irrigation equipment for growing oranges.

John spent much of his time on the island of Cyprus. In 1926, his childhood sweetheart Jessie travelled out alone to Egypt, carrying a large box containing a wedding cake made by her mother. John and Jessie met at Pot Said in Egypt where they were married by the British Consul.

After a honeymoon in Egypt they moved to Cyprus, first living in Nicosia, then settling in Famagusta. John exported a beautiful Belsize sports car which, according to a local doctor, was “quite a headturner”.

In 1928, tragedy hit the family with the death of Jack Jnr’s father, grandmother, and brother Norman, who died following an accident in his Salmson sports car. John returned to Manchester, sold the family home in Marshall Road, Levenshulme, and took his mother back to live with them in Cyprus.

In 1930, John H Newall was born, who would eventually be at the helm of CPE for many years.

Jack Jnr continued to grow the import export business, and won the contract to supply the entire diesel electric generating plant to Cyprus Mines Corporation in 1930s.

On July 1st 1939, business was booming and the Newall clan decided to take a holiday to visit relations in England. The family Jack Jr, Jessie, Joan, John H Newall and Joy all left their house, their dog and their possessions and embarked on a long trip back to England. They arrived at Avonmouth Dock where they collected a brand new Morris 10 motor car, which they planned to export on their return trip to Cyprus.

Unfortunately, 1939 was not a good year to travel. World War II broke out during their stay and they were unable to return to Cyprus. All their possessions, including the furniture, the grand piano, the Belsize car and kids toys were auctioned off and the import export business ceased to trade.

During the war years, Jack Jnr worked on Crossley 500HP marine diesel engines for minesweepers.

The Post War Era.

In the 1940s Jack Jnr set up Compressor & Power Engineers in the corner of a carpentry shop in Blackheath, Birmingham. CPE moved to Rea Street, Birmingham in 1950 then to West Bromwich in 1952 (see picture).

During the post war years CPE designed and built many innovative products. The first products were double stage compressed air filters, supplied to Rolls Royce and Lucas Gas Turbine Equipment. Other products included a pneumatic paint stirrer, which was still being used by Rolls Royce cars up until the 1990s and a range of air compressors.

In 1960, John H Newall, Ted Scanes and Jim Hartshorne all attended a night school class to learn how to weld. CPE began to manufacture their own filter housings and air receivers.

In 1970, CPE moved to their current premises in Tamworth. During the 1970s CPE mainly produced filters and driers for compressed air systems. Innovative designs included cyclonic separators (a technique since used by vacuum cleaner manufacturers) muliti stage filters and supremely reliable automatic drain valves. CPE also produced air receivers for their range of compressors and filter housings for their many designs of filters.

During the 1980s CPE became more involved in the manufacture of air receivers and over the next 10 years began to produce more specialised work such as stainless steel vessels and offshore specification vessels. CPE progressed into a producer of high quality pressure vessels and established its excellent reputation for quality pressure vessels.

In 1992, Stephen Newall joined the company to add a 4th generation to the family business.

The company has steadily grown in size with the building being expanded twice in 1990 and 2007.

In 2013, CPE opened Anders Works, a brand new purpose built pressure vessel shop

CPE now has excellent facilities for manufacture of vessels with a brand new stainless steel workshop and upgraded lifting capacity. With these new facilities, production is now more efficient than ever.

CPE still aims to offer the same levels of service, quality and value on which it has built such a wonderful reputation.

CPE are pleased to announce that we now have DNV shop approval.

We now have DNV Approval of Manufacturer Certificate, this covers the Manufacture of pressure equipment and the manufacture of welded products in our welding workshop.

To find out more about our approvals and accreditation Click Here