We will be shut from 22/12/2023 and returning to the office on 02/01/2024.

We would like to wish you all a Merry Christmas and a Happy New Year.

Keep up to date with our latest news by following our LinkedIn Page

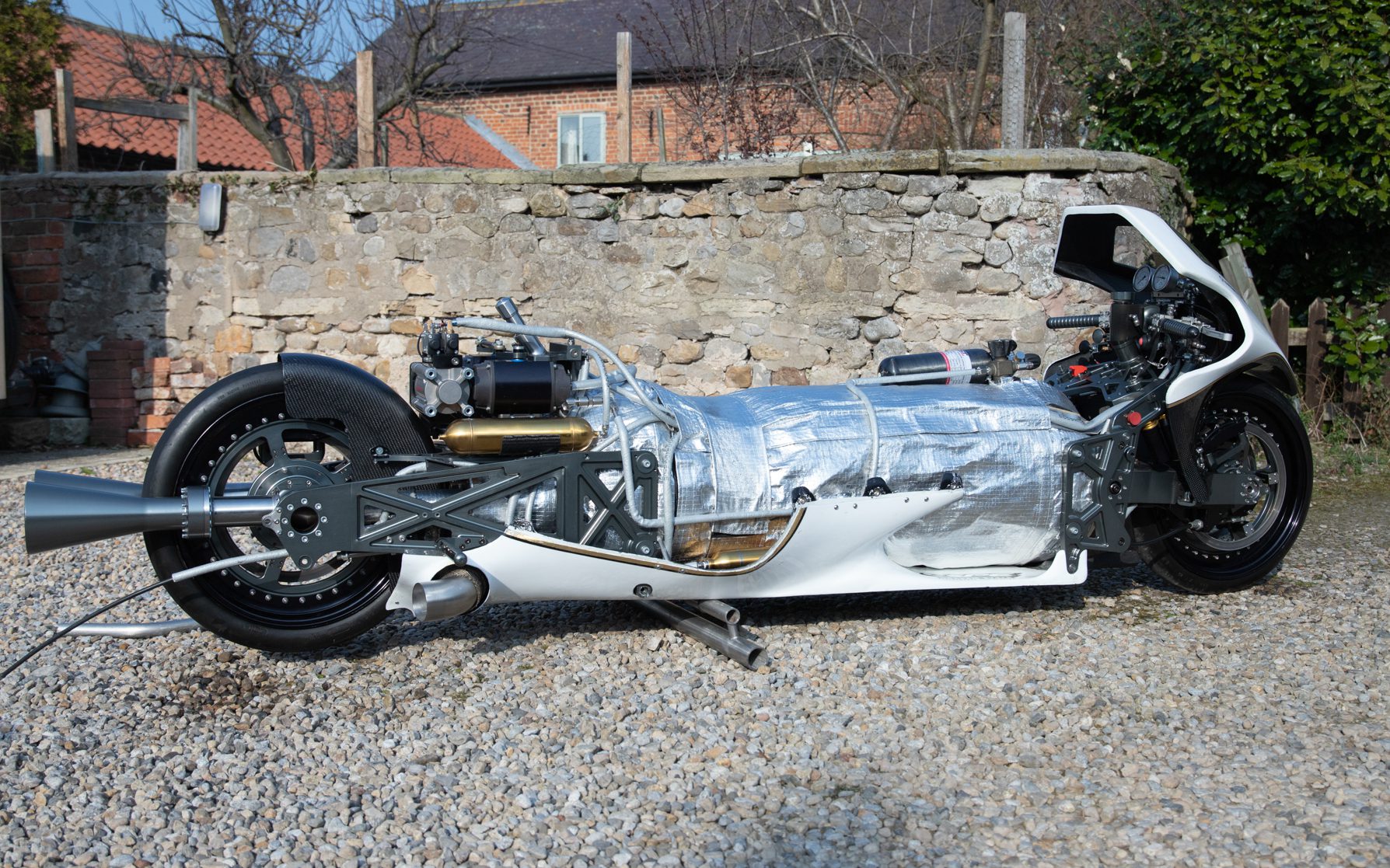

Steam Rocket Bike Breaks the Land Speed Record. On 21st May 2023, Graham Sykes clocked a top speed of 163.8mph as he completed the 1/8th-mile drag run in just 3.878 seconds and then on 7th July 2023 at Santa Pod Raceway Graham ran a time of 6.7189 seconds over the standing 1/4 mile track with a 1.0605 60ft. The 1/8 mile time and speed were 4.038 at a staggering 175.06mph which takes the record for a steam-powered vehicle to over 175mph!

At CPE we are super proud of Graham and his team’s achievements, it has been fantastic to support the project and see it succeed.

To Find out more about the Steam Rocket Bike Breaks and the pressure vessel that powers it click here

For more information on the Force Of Nature project: Force Of Nature Website and Facebook Page

Congratulation to Dan and Ben from our Pressure Test and Dispatch team who attended and passed a Level 1 course in Penetrant testing. This allows them to be certified to PCN level 1 to perform DPI testing under the supervision of our level 2 personnel. We use DPI to check the surface of our welding and materials to ensure that the products are high quality.

The course covered the following areas:

- Set up Penetrant Testing equipment;

- Perform the Penetrant Inspection tests;

- Record and classify the results of the tests according to written criteria;

- Report the results

Penetrant testing passed by our pressure test and dispatch team

Click here for more information about what we can offer

Keep up to date with our latest news on LinkedIn

Last week At CPE we passed our 3 year ASME U Stamp renewal reveiw. This is done by the American Society of Mechanical Engineers (ASME) team leader under Section VIII Div. 1 and covers the U, UM and R stamp which is issued by the National Board. The audit is completed over 2 days by the ASME team leader and required alot of effort and time by our design and quality team to ensure that all our systems are opperating correctly and complying with the ASME U Stamp requirements. Great work by the team to ensure the review went smoothly and we can continue supplying pressure vessels with the ASME Certification mark with the U designator. Along with the UM designator (miniature vessels).

To find out more about our ASME Accreditiation click here

Keep up to date with our latest news on LinkedIn

We have made some improvements to our Anders workshop facilities, improving the safety, working conditions and look of the workshop.

We have upgraded the lighting to new LED lights giving 304500 lm and around a 50% reduction in power consumption. we’ve also added a resin floor and new welding curtains.

- LED lights giving 304500 lm

- 50% reduction in power consumption

- Fully segregated stainless steel workshop

We’ve now been in our purpose-built Anders workshop for 10 years. Anders is our fully segregated Stainless steel workshop where we produce the majority of our work, we regularly make Pressure Vessels, Air Receivers, Heater Housings, Filtration Vessels, DWI Water Vessels and Pipework.

Click here to see our recent Projects

Click here for more information on Pressure Vessels

Keep up to date with our latest news on LinkedIn

We will be shut from 24/12/2022 returning to the office on 03/01/2023.

We would like to wish you all a Merry Christmas and a Happy New Year.

Keep up to date with our latest news by following our LinkedIn Page

At CPE we take health and safety very seriously. We are pressure testing vessels and components up to 1200 Bar G every day. We use a combination of external & internal training courses to ensure our test bay operatives are always safe & aware of the dangers. Recently we’ve had some of the new team members attend a 2-day Hydrostatic Pressure Testing Training Course. They covered the practical and theoretical aspects of pressure testing, covering thread awareness and the tightening of connectors. We have invested heavily in purpose-built pressure rigs, pumps & bulletproof screens to keep risk to a minimum.

For more information on our HSEQ Assurance click here

Click here for more information on Pressure Vessels

Keep up to date with our latest news on LinkedIn

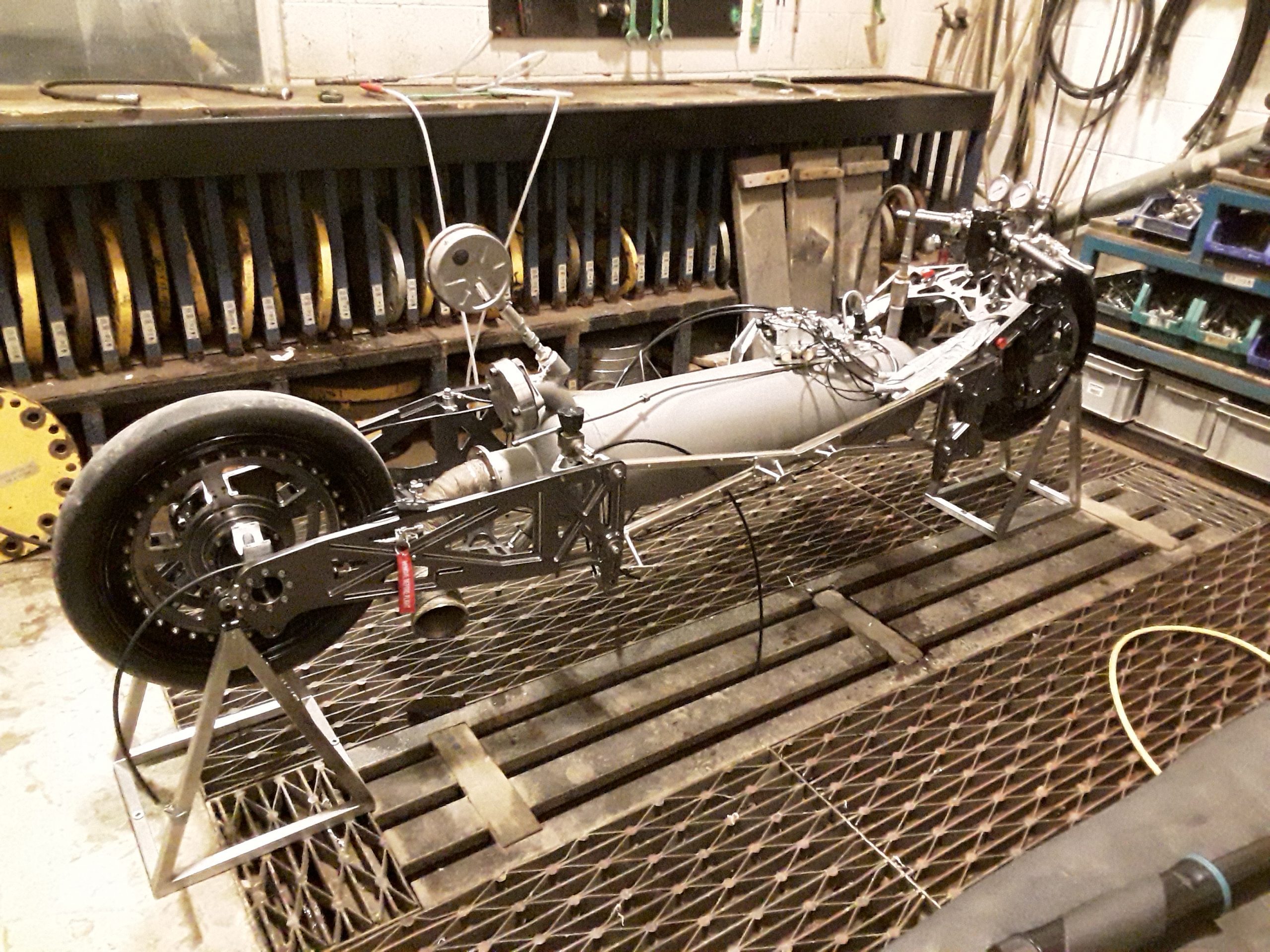

Over the last 10 years, we have supported Graham Sykes on his Force Of Nature Steam Rocket Bike project. The project aimed to produce a steam-powered rocket bike with unique green credentials and the potential to reach 200mph making it the fastest Steam powered vehicle ever.

The bike works by superheating pure water to create pressure. Once the correct pressure is achieved the water is then passed through a specially shaped nozzle, the superheated water flashes to steam as it escapes through the de Laval nozzle creating rocket propulsion until the bike’s pressure vessel is empty. The heat is generated by using hydrogenated vegetable oil to reach 200°C and 30 bar pressure.

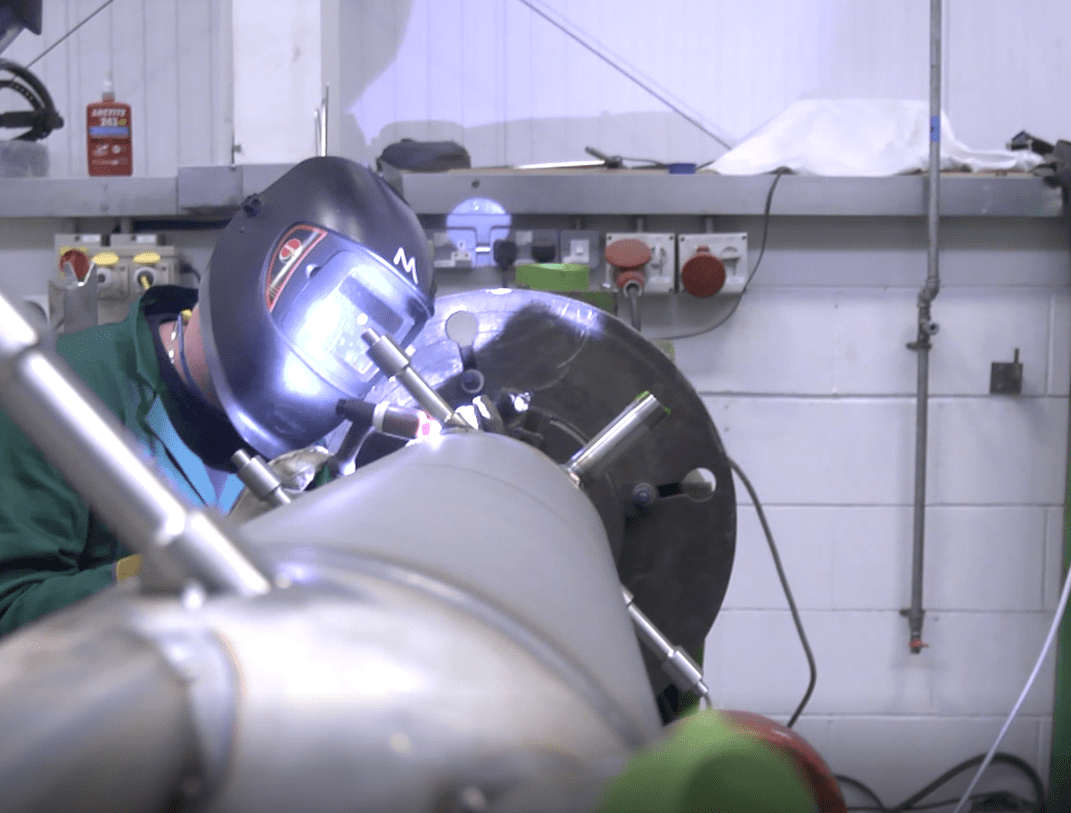

We designed, manufactured and certified the pressure vessel to meet Graham’s specifications at our Tamworth facility. The vessel required custom-made parts and specific dimensions to help optimise the bike’s performance. Initially, we made a 50 litre Stainless Steel 316/L vessel and then after testing we made a 130 Litre vessel to increase the capacity of the bike, heating tubes run through the vessel to get the water to 200°C.

Team Force of Nature:

The force of nature team is a small family-run precision engineering company, Graham Sykes and his wife, Diane.

Chief designer and engineer Graham Sykes has been involved in straight-line motorsport since 1979. Graham has worked on many prestigious projects including six years as race engineer for Vauxhall’s championship-winning British and European Touring Car Team, engineer and key team member for the ‘Firestorm’ jet-powered dragster and is currently part of the engineering team working on ’52 Express’, a world land speed record motorcycle. Graham is the current British land speed record holder for a 3-wheeled vehicle achieved with his self-designed and engineered V8 engined ‘Syko’.

Graham’s wife Diane takes on the role of financial director and purchaser. Not unfamiliar with motorsport Diane has been inherently involved in running the bikes for the last 22 years; crewing for the team on the start line and towing the bike back after completing runs. Diane’s strengths also come into play with the administration/accounts, travel logistics and hospitality, something every project is lost without.”

A full article was featured in Race Engine Technology – Issue 139

For more information on the Force Of Nature project: Force Of Nature Website and Facebook Page

for more on CPE see the following links:

Click here to see more Projects

Click here for more information on Pressure Vessels

Keep up to date with our latest news on LinkedIn

Thanks to Graham Sykes and Becki Ellis Photography for the photos.

Congratulations to Mitul for getting his CSWIP Visual Welding Inspection qualification. Mital is a vital part of our quality team whose role is to help to maintain our high standards across all our products. The CSWIP Visual Welding Inspection course is aimed at welding inspectors and will help to improve their inspection skills. At CPE we are constantly investing in our team and looking to improve our skills.

For more information on our design and technical capabilities click here

Click here to see more Projects

Keep up to date with our latest news on LinkedIn

CPE are delighted to announce that we are opening a new facility the Neander Works which will be a Clean Energy Workshop. Located in close proximity to our existing two workshops and head office. Neander Works will service our increasing demand for fabrications in the Clean Energy Sector. The requirement to increase our capacity came following securing major contracts for the Hydrogen Market.

For more information on how we support the Clean Energy Industry see the Clean Energy Page or get in contact

Keep up to date with our latest news on LinkedIn